Target (Setpoint) and Actual (Live) Data in BMW DIS

Within any vehicle's ECU, there are two types of information:

- Input (incoming);

- Output (outgoing).

Input information, in turn, can be divided into two subtypes:

- Primary;

- Secondary (verification).

Input information is sent to the ECU from various sensors, potentiometers, etc.

Output information is sent from the ECU to various actuators. For example:

- Idle Air Control (IAC) valve opening angle;

- Air conditioning clutch engagement;

- Fuel metering rack position in the injection pump;

- Injector opening signal, etc.

Primary information (temperature sensors, camshaft position sensor (CPS), crankshaft position sensor (CKP), mass airflow sensor (MAF), etc.) is used by the ECU for necessary calculations based on its embedded firmware. For example:

- How much fuel to inject for 10 kg of incoming air;

- What injection/ignition timing advance to set if the engine temperature is 92 °C;

- How long to glow the pre-heater plugs if the engine temperature is -10 °C.

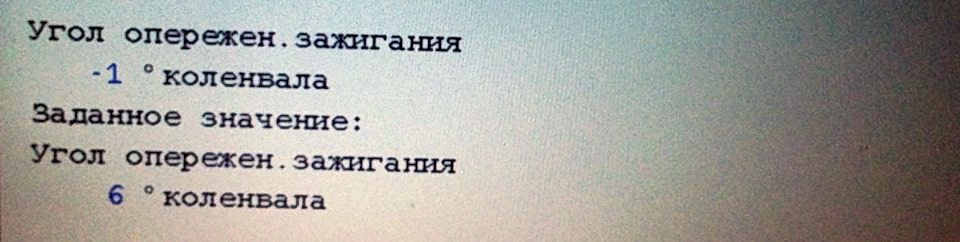

For a fully functional vehicle system operating in a vacuum, primary input and output information would be sufficient. For instance: based on primary input, the ECU commands the actuators to perform an injection/ignition advance of 5° before Top Dead Center (TDC). However, due to various faults (stretched timing chain, incorrect valve timing, etc.), the actual achieved advance might be only 2° before TDC. This results in poor engine operation. Therefore, the ECU needs to verify how the commanded action was actually (factually) executed to calculate necessary corrections, adjustments, and adaptations. This is where secondary (verification) input information comes to the ECU's aid.

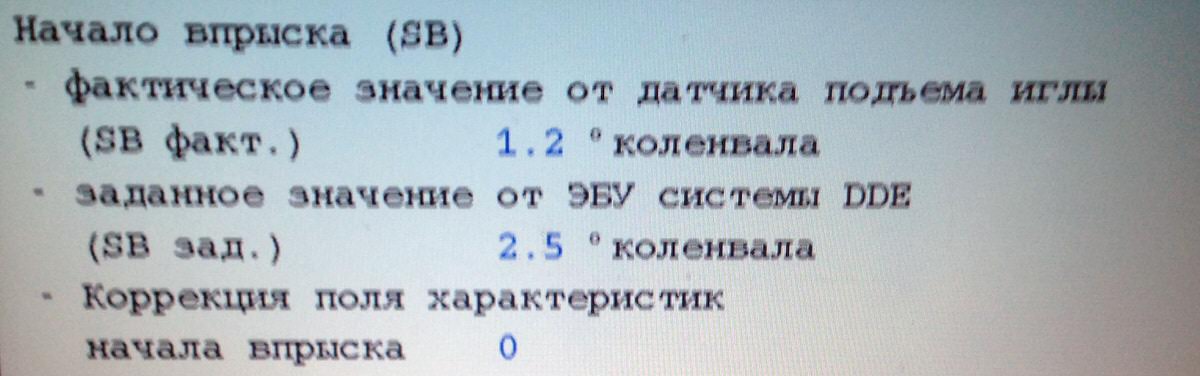

Secondary (verification) input information serves to check the accuracy of executed commands. For example:

- The fuel metering rack in the injection pump assumes a commanded position for the required fuel delivery based on a signal from the ECU, while the rack's potentiometer reports back to the ECU the rack's actual position (the accuracy of the command execution);

- The start-of-injection sensor allows determining the actual injection/ignition timing advance value;

- The lambda (oxygen) sensor allows verifying the accuracy of the air-fuel mixture preparation and combustion.

Based on this verification data, the DME (engine ECU) can identify a fault in a component, calculate corrections to compensate for wear or breakdowns, or identify and store a fault code. Most often, separate sensors, distinct from the primary ones, are responsible for providing this verification information.

Thus:

Target (Setpoint) Value — output commands sent from the ECU to the actuators.

Actual (Live) Value — primary and secondary (verification) input information received by the ECU from its sensors.