Real-time and actual data in BMW DIS

Any car ECU has 2 types of information:

— incoming;

— outgoing.

In turn incoming information can be divided into two subtypes:

— primary;

— secondary (verification).

Incoming information enters the ECU from various sensors, potentiometers, etc.

Outgoing information is sent from the ECU to various executive bodies. For example:

— opening angle of the idle air valve;

— air conditioner clutch closure;

— fuel dispenser in the injection pump;

— injector opening signal, etc

Primary information (temperature sensors, DPRV, DPKV, DMRV, etc.) is used by the ECU for the necessary calculations based on the hardwired firmware. For example:

— how much fuel to supply for 10 kg of exhaust air;

— what to set the injection/ignition advance angle if the engine temperature is 92 °С;

— How long to heat glow plugs? if the engine temperature is -10 °С.

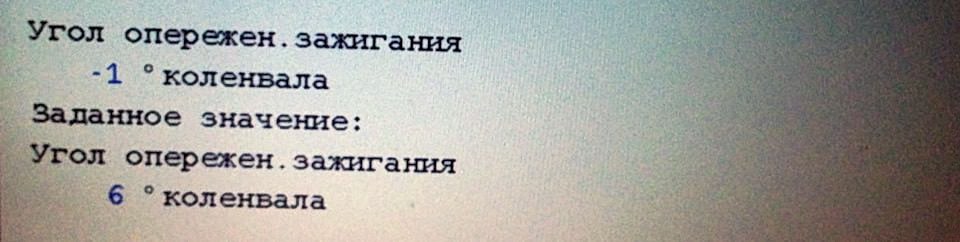

On a fully repaired car assembly, located in a vacuum, there is enough primary incoming and outgoing information. For example: based on the primary incoming information, the ECU instructs the execution authorities to advance the ignition/injection by 5° to TDC. But due to various malfunctions (stretched chain, broken timing phase, etc.), the advance angle is only 2° to TDC. We get poor engine performance. According to this, the ECU must check how the given command was actually (actually) executed, for further calculations of the necessary amendments, corrections and adaptations. And secondary (verification) information comes to the aid of the ECU.

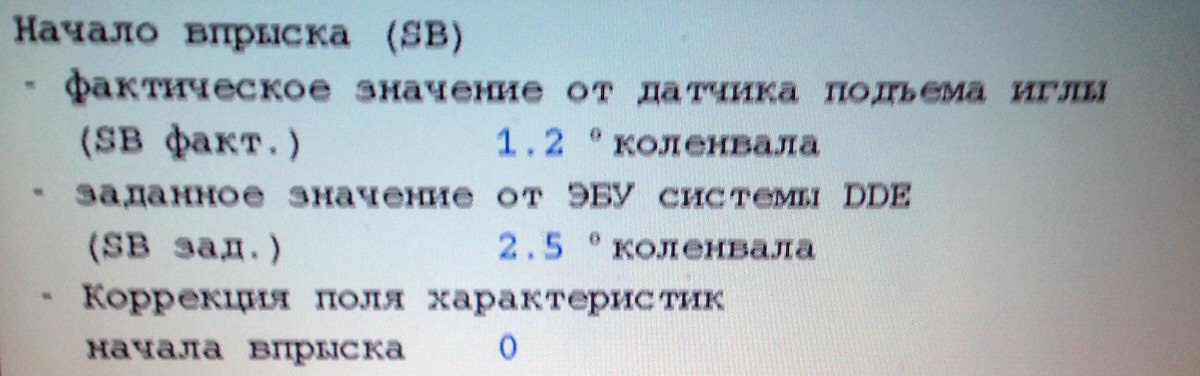

Secondary (verification) incoming information is used to verify the accuracy of the execution of given commands. For example:

— the fuel dispenser in the high-pressure fuel injection pump takes a given position for the required fuel supply based on a command from the ECU, and the fuel dispenser potentiometer informs the ECU about the actual position of the fuel dispenser (the accuracy of the execution of the given command);

— the injection start sensor allows you to find out the actual value of the injection/ignition timing angle;

— the lambda probe allows you to find out the accuracy of the preparation and combustion of the fuel-air mixture.

Based on the verification information, DME can learn about the malfunction of any component, calculate corrections to compensate for wear, breakdowns, or identify and save the error. Most often, separate sensors from the primary one are responsible for verification information..

Thus:

Set value — outgoing commands sent from the ECU to the execution authorities.

Actual value — primary and secondary (test) incoming information entering the ECU from sensors.