Troubleshooting Fluctuating Idle on the BMW M51 Diesel Engine

One of the most common issues with the M51 engine is a fluctuating idle speed. The root cause lies in the fuel injection pump equipped with a potentiometric fuel rack position sensor, colloquially known as the "potentiometer" or "resistor head." The solution is quite straightforward: replace the injection pump with a known-good unit featuring a resistive head, or switch to a pump with an inductive fuel rack position sensor, colloquially known as the "inductive head" or "inductive pickup," which can be considered virtually everlasting. Unfortunately, the inductive head is not a panacea. While it doesn't suffer from idle fluctuation, it has its own set of characteristic issues, such as hesitation during acceleration.

So, why do the RPMs start to fluctuate in the first place?

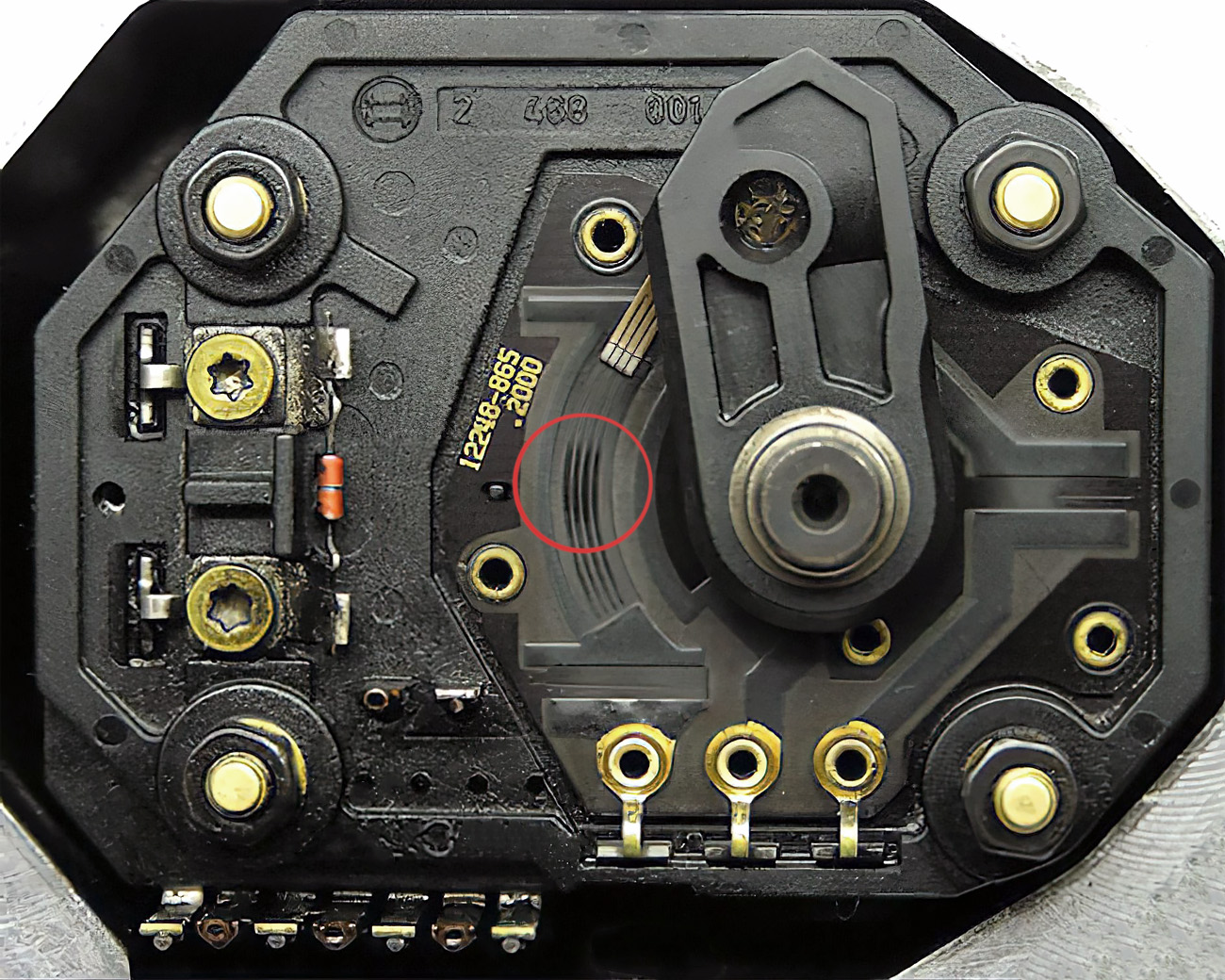

To understand this, one must first grasp the concept of target vs actual values in the engine control loop. The fuel rack actuator is moved by a proportional solenoid. Its design, of course, cannot be simply called an electric motor, but if a gross simplification is needed – it can serve. By varying the voltage applied to the solenoid, we change the position of the fuel control sleeve, and thus the amount of fuel delivered to the engine. However, we cannot know with high precision the exact position the rack assumes after the voltage is applied. One could, of course, build graphs of sleeve displacement versus the magnitude and duration of the applied voltage/current. The result would resemble a kind of inertial navigation system (INS) for the fuel rack. But for fine-tuning engine operation, much higher accuracy is required. Therefore, precise position determination is handled by a potentiometer – essentially a variable resistor – rigidly connected to the fuel control sleeve. By changing the sleeve position via the solenoid, we also alter the position of the potentiometer's contacts (wipers) on its conductive tracks. Knowing the position of the potentiometer's contacts means we know the exact position of the fuel control sleeve.

These two elements are responsible for altering and controlling the diesel engine's RPM, in our case, at idle. Injection timing is certainly a crucial aspect of diesel operation, but it has no direct relation to RPM control.

The potentiometric sensor has conductive tracks uniformly coated with a resistive layer. The further the potentiometer wipers are from the beginning of the tracks (the power connection point), the higher the resistance of the layer, and the greater the voltage drop at the point of contact between the wipers and the track. By having a map of the voltage change along the entire track length and knowing the current voltage at the potentiometer, one can determine the current position of the fuel control sleeve with high accuracy. Unfortunately, the resistive layer is not eternal, and the constant movement of the wipers gradually wears it down.

At the spot where the resistive layer wears thin, an artifact appears, causing a sharp spike in resistance and, consequently, a voltage jump. The DDE control unit will interpret this as a decrease in fuel delivery and will command the fuel control sleeve to move towards increasing the fuel quantity. When the potentiometer wipers move onto an area with a thicker resistive coating, the DDE will reduce fuel delivery to maintain the target idle speed. As long as the wipers pass through the artifact zone, this cycle of fuel corrections will be endless. Since diesel engine RPM is directly dependent on the amount of fuel injected, the artifact will specifically affect it.

Why does this manifest primarily at idle?

In fact, this is one of the fundamental reasons for introducing start-stop systems in engines. If you consider a large timeframe of engine operation, it turns out that the engine spends most of its time at idle. The main reasons for this are traffic jams, congestion, and traffic lights. Idle occupies a very narrow part of the entire operating range of a warmed-up engine – 700 to 800 RPM, which, incidentally, is only about 2% of the possible range. Consequently, the wipers spend most of their time moving over a very small section of the resistive layer, wearing it out maximally. And at some point, the artifact will appear precisely in the area responsible for controlling fuel delivery at idle.

What can be done?

There's essentially no sense in investing in repairing the resistive head of the M51 injection pump. Replacing the resistive layer is impossible. Well, of course, it's possible with a laboratory, special equipment, technical documentation, as well as education, knowledge, and experience. In other words, it's impossible for the average car owner. Some craftsmen sell new PCB boards with a resistive layer, but replacing it is complex, and its service life is rather short.

A used injection pump with a potentiometric fuel rack position sensor can be checked for artifacts before purchase, even without disassembly, by applying voltage to the solenoid and monitoring the potentiometer readings. However, if you're building the car as a long-term keeper, the only option worth considering is switching to an injection pump with an inductive fuel rack position sensor. Investing in the repair of such a head is justified, and it will serve faithfully for many more years. But as I wrote at the very beginning, there's nothing inherently wrong with the resistive head – the key is to find a live, functional specimen.

And that's it? Nothing else can be done?

Not quite! In theory, if you can permanently move the potentiometer's operating point away from the artifact zone, you may never encounter this problem again. This requires either lowering or raising the idle speed. Lower idle RPM won't allow powering energy-hungry accessories like the automatic transmission or air conditioning, and when transitioning from idle to partial or full load, the potentiometer will still pass through the artifact zone. Therefore, the only viable option is to increase the idle speed. Using DIS, you can add up to 91 RPM to the base idle setting. Considering the standard idle is around 700-750 RPM, after adjustment, you'll get a figure of 800-850 RPM. An acceptable frequency for constant use. However, in my experience, this is not always enough to completely move the potentiometer away from the artifact zone. The maximum idle speed for the M51 engine is 1200 RPM, the so-called warm-up mode. To achieve it, it's enough to signal the DDE that the ambient temperature is very low. That is, to disconnect the connector from the engine coolant temperature sensor used by the DDE.

Unfortunately, such an idle speed is too fuel-thirsty, so this can only be considered a temporary repair, for when the car is needed for an indefinite but limited period. The warm-up mode RPM can be partially adjusted; it's enough to adjust the resistance on the sensor connector. By making the DDE believe the coolant temperature is around -5 degrees Celsius, you can achieve, for example, 900 RPM.