Correction of floating engine speed of BMW M51

One of the most common problems with the M51 engine is floating idle speed. Its roots go back to the fuel injection pump with a potentiometric dispenser position sensor, popularly known as a “resistive head”. The solution is quite simple, replacing the fuel injection pump with a “live” copy with a resistive head, or switching to a fuel injection pump with an induction dispenser position sensor, popularly known as an “induction head”, which can be called eternal. Unfortunately, the induction head is not a panacea at all. Yes, it does not have the problem of floating speed, but it also has many of its own, for example, failures during acceleration.

Why might the revs start to fluctuate?

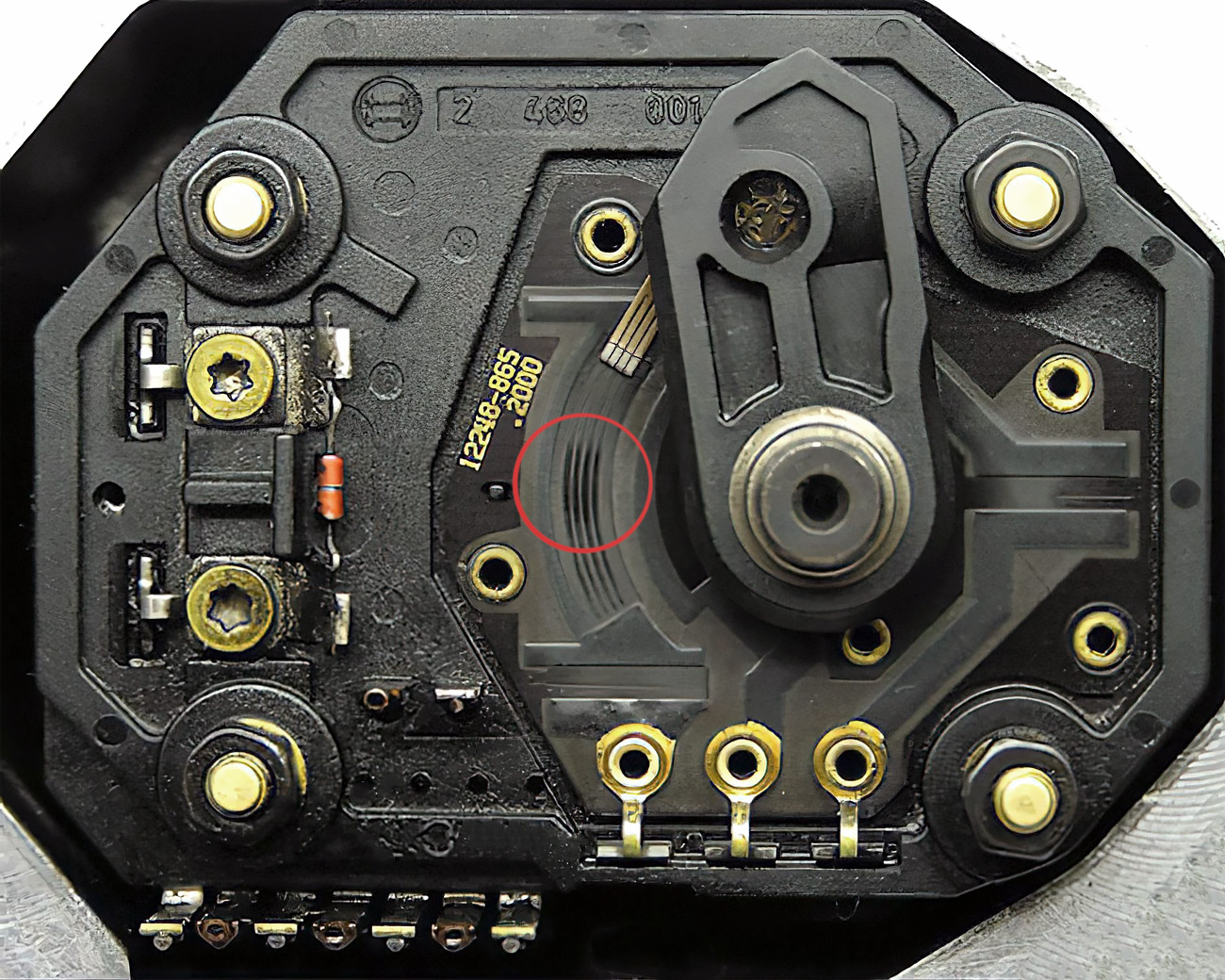

I suggest you first read about real and actual data, it was not in vain that I wrote. The metering drive is moved by a proportional electromagnet. Its design, of course, cannot be called just an electric motor, but if you need to greatly simplify it, then it can be done. By changing the voltage supplied to the electromagnet, we change the position of the metering sleeve, and therefore the amount of fuel supplied to the engine. But we cannot know with high accuracy the position of the dispenser that it occupied after voltage was applied to it. Of course, you can plot the dependence of the sleeve movement on the magnitude of the applied voltage and its duration. The result will be some kind of analogue of inertial navigation. But to fine-tune the operation of the engine, much higher precision is needed. According to this, the position is determined by a potentiometer, essentially a variable resistor, which is rigidly fixed to the fuel metering sleeve. By changing the position of the bushing using an electromagnet, we also change the position of the contacts (brushes) of the potentiometer on the conductive paths. Knowing the position of the potentiometer contacts, we know the exact position of the dispenser sleeve.

Thanks to these two elements, the speed of the diesel engine is changed and controlled, in our case idle speed. The injection advance angle is, of course, an important component of the operation of a diesel engine, but has nothing to do with speed.

The potentiometric sensor has contact tracks uniformly covered with a resistive layer. The further the potentiometer brushes are from the beginning of the tracks (the place where the tracks are connected to the power supply), the higher the resistance of the resistive layer, and the more the voltage drops at the point of contact of the brushes with the track. Having a map of voltage changes along the entire length of the tracks, and knowing the current voltage on the potentiometer, you can find out with high accuracy the current position of the fuel metering bushing. Unfortunately, the resistive layer does not last forever, and gradually the movement of the brushes wears it out.

At the point where the resistive layer is abraded, there will be an artifact when the voltage increases sharply. The DDE control unit will perceive this as a decrease in fuel supply and will change the position of the metering sleeve in the direction of increasing the amount of fuel supplied. When the potentiometer brushes reach a thicker layer of resistive coating, the DDE will reduce the fuel supply to maintain idle speed. As long as the potentiometer brushes hit the artifact locations, the cycle of fuel supply adjustments will be endless. Since diesel speed depends on the amount of fuel supplied, the artifact will affect them specifically.

Does this only appear at idle?

In general, this is one of the main reasons for the introduction of a start-stop system in engines. If we take a long period of engine operation, it turns out that most of the time the engine is in idle mode. The main reasons for this: traffic jams, congestion, traffic lights. Idle speed occupies a very small part of the entire operating range of a warm engine, 700 - 800 rpm, and this, by the way, is only 2% of the possible range. Accordingly, the brushes will move most of the time over a very small area of the resistive layer, wearing it out as much as possible. And at one point the artifact will appear exactly in the place responsible for controlling the fuel supply at idle..

How is it possible to fix this?

As such, there is no reason to invest in repairing the resistive head of the M51 fuel injection pump. It is impossible to replace the resistive layer. Although, of course, it is possible, having a laboratory, special equipment and technical support. documentation, as well as education, knowledge and experience. That is, it is impossible for a simple car enthusiast. Some craftsmen sell new boards with a resistive layer, but replacing it is difficult and the resource is quite short.

A used fuel injection pump with a potentiometric fuel metering position sensor, before purchasing, can be checked for the presence of an artifact without even disassembling it. By applying voltage to the electromagnet and monitoring the potentiometer readings. But if you make a car, as they say, for yourself, then you should only consider switching to a fuel injection pump with an inductive fuel metering position sensor. You can invest money in repairing such a head and it will serve faithfully for many more years. But as I already wrote at the very beginning, there is nothing wrong with a resistive head, the main thing is to find a living specimen.

And nothing more?

In theory, if you permanently remove the potentiometer from the place with the artifact, then you may never encounter this problem again. It is necessary to lower or increase the idle speed. Low idle speed will not allow powering power-hungry electrical appliances, automatic transmissions or air conditioning, and when switching from idle mode to partial or full load mode, the potentiometer will still pass through a place with an artifact. Therefore, the only option is to increase the idle speed. With DIS you can add up to 91 rpm to idle. If we consider that the standard idle speed is around 700-750, then after adjustment we will get a mark of 800-850 rpm. Acceptable frequency for continuous use. But in my practice, this is not always enough to completely remove the potentiometer from the place with the artifact. The maximum idle speed of the M51 engine is 1200 rpm, the so-called warm-up mode. To achieve this, it is enough to inform DDE that the ambient temperature is very low. That is, remove the chip from the engine coolant temperature sensor that uses DDE.

Unfortunately, this idle speed is too voracious in terms of fuel consumption, so this can be called a temporary repair if the car is needed for an indefinite amount of time. You can partially regulate the speed of the warm-up mode, just play with the resistance on the sensor chip, informing DDE about -5 degrees Celsius of the coolant, you can achieve, for example, 900 rpm.